Sheet metal processing services

Experience and technology in sheet metal processing

Since 1972, ARTIL has been a benchmark in sheet metal processing for third parties. The company, located in the province of Bologna, offers a comprehensive service covering all stages of the production process, from initial cutting to the finished product. The combination of extensive experience, advanced technologies, and a team of qualified professionals ensures a comprehensive, quality approach, ideal for meeting the needs of diverse sectors such as furniture, lighting, medical, agricultural, and pharmaceuticals.

ARTIL's goal is to provide precise, reliable, and customized solutions, always ensuring the highest level of efficiency and competitiveness.

Latest generation technologies for laser cutting

2D laser cutting

The 2D laser cutting department uses 4000-watt TruLaser systems, capable of high-precision machining on work surfaces up to 1500x3000 mm. Thicknesses of up to 15 mm for stainless steel and 20 mm for iron can be processed, achieving optimal results even for the most complex projects.

3D laser cutting

Thanks to the TruLaserCell 7040 system, ARTIL also offers 3D laser cutting, which allows the production of three-dimensional components in stainless steel and iron with thicknesses up to 5 mm. This technology enables the development of customized solutions for advanced geometries and customized applications.

Spinning and flow forming

Another strength of ARTIL's services is spin turning, supported by nine lathes capable of processing up to 2000 mm in diameter. The company works with a variety of materials, including stainless steel, iron, aluminum, brass, and copper, with varying thicknesses that ensure maximum versatility. Flow forming allows for precise and durable shapes, ideal for technical applications in various industrial sectors.

Welding and assembly

ARTIL has a specialized TIG and MIG welding department, supported by modern manual 3D laser welding technology. This combination allows for strong and durable joints on any metal, with high-quality finishes. The assembly phase is meticulously managed to provide the customer with a finished product that meets their specifications.

Light carpentry and custom solutions

The company also specializes in the production of lightweight carpentry in stainless steel, iron, and aluminum. Each project is handled from conception to delivery, with a personalized approach that allows for the development of unique solutions to meet functional and aesthetic needs. The experience gained in over fifty years of business makes ARTIL a reliable and qualified partner for all your sheet metal processing needs.

Why choose ARTIL?

ARTIL is the ideal partner for sheet metal processing in Bologna and throughout Italy. Thanks to our experience and advanced technologies, we can offer customized solutions for every project. Discover the benefits of choosing ARTIL for your metalworking needs.

Over 50 years of experience in sheet metal working.

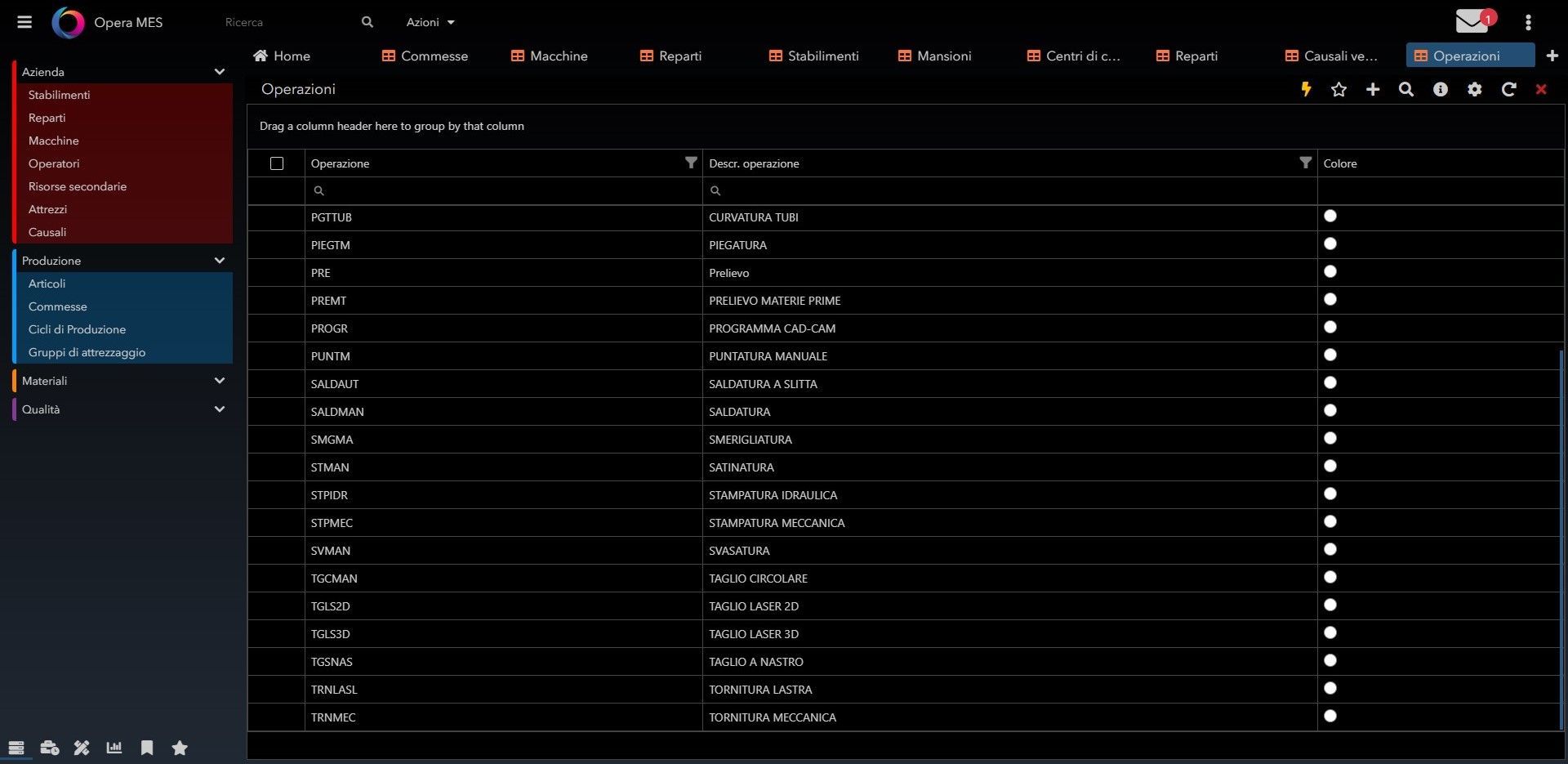

Advanced technologies, such as CAD-CAM stations and latest-generation laser systems.

Professionalism and precision in every phase of the production process.

Contact us to learn more about our sheet metal processing services and request a personalized consultation.

Latest news